The Importance of Sanitation After Maintenance

Whether a minor repair or a major project, all projects are more successful with prior planning, clear communication, and engaging the appropriate subject-matter experts. In a food plant, subject-matter experts can:

- Identify the risks and preventive controls needed during food production facility repairs and projects to ensure that all physical, chemical, and microbiological risks are managed.

- Aid in hygienic design reviews and ensure new or modified equipment and infrastructure are cleanable.

- Develop a realistic timeline that includes vital post-project or repair procedures, and verifications that ensure effective hygienic conditions, food safety, and product quality are maintained.

While all of these are critical to any project or repair, this article will focus on the latter: the importance of sanitation after maintenance.

Sanitation After Maintenance

Food manufacturing facility maintenance is never-ending. There are always necessary repairs, modifications, and preventive maintenance (PM) for equipment, utilities, and infrastructure. Equipment and infrastructure maintenance are important to food production efficiency, food and employee safety, and product quality. Just as important to food safety and product quality is a robust sanitation-after-maintenance program that ensures the food production equipment and environment are effectively cleaned after any potentially contaminating work is completed.

Program Development

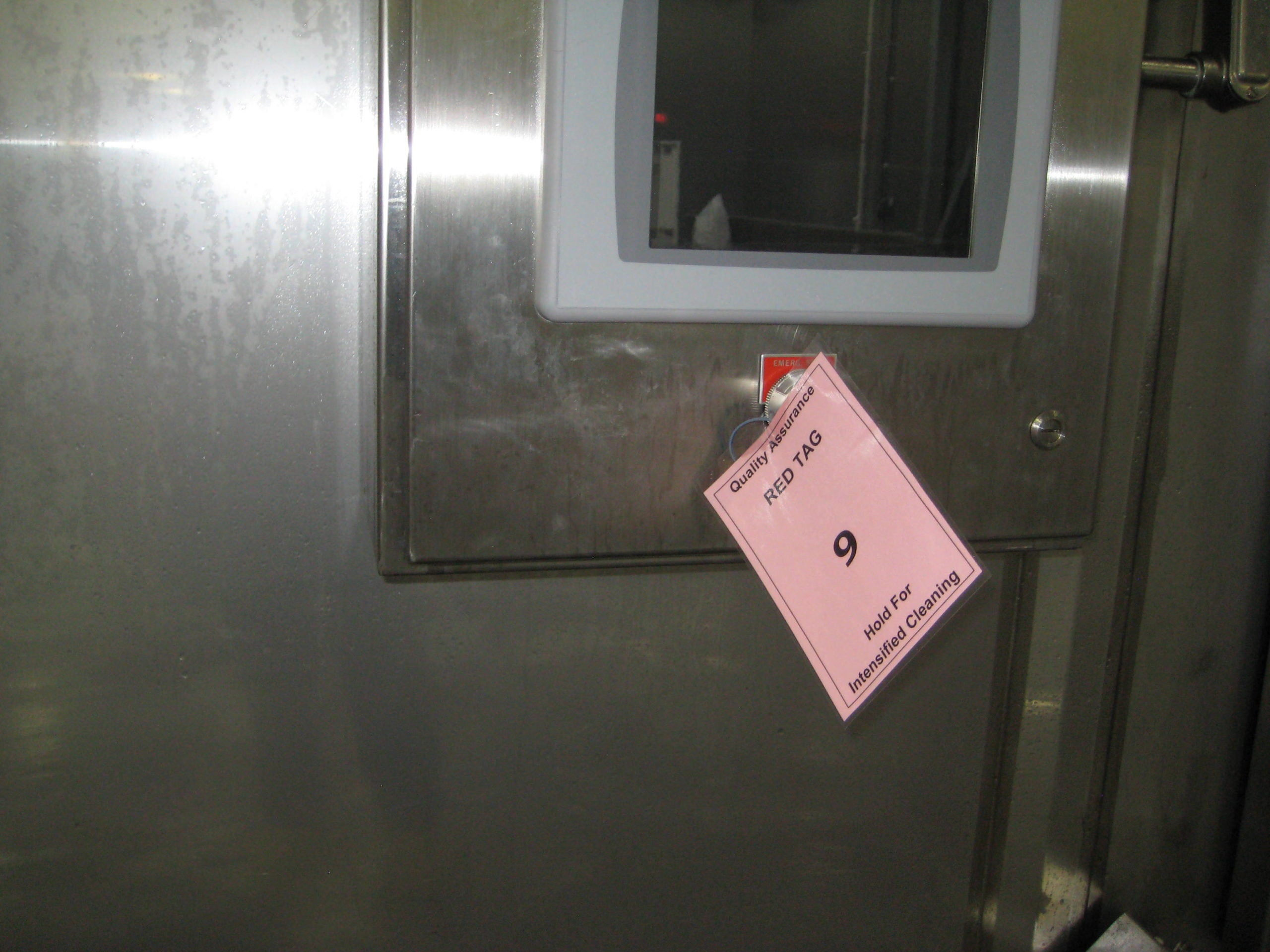

Effective sanitation after maintenance should include written guidelines that define how the program is designed to work and who is responsible for each stage. It is also important to determine what types of work require a sanitation-after-maintenance intervention prior to producing food. A sanitation-after-maintenance program—sometimes referred to as a red tag program—should include a tag that is attached to equipment or a room entrance during infrastructure work or repairs. This tag should include:

- The type of repairs completed and documented by maintenance, including documented tool and part accountability. If a work order is used, the work order number should also be documented.

- The type of cleaning completed by sanitation or other trained personnel. Post-cleaning practices should be applicable to the type of repairs or modifications completed and support food safety.

- Post sanitation-after-maintenance inspection, including a copy of the facility’s pre-operational inspection form.

- Document review and verification to ensure all sections are documented completely and accurately.

Sanitation-after-maintenance programs should include a mechanism to ensure that all tags created are completely closed. Successful sanitation-after-maintenance programs are linked to food manufacturing facility PM work order programs in which work orders are not closed until the tag is returned. Connection to a facility’s PM program also enables creation of a sanitation-after-maintenance log that provides closure documentation on all sanitation-after-maintenance tags.

Program Execution

Once the program is developed, it is essential to effectively communicate the program. All associates must be trained on how the program works: maintenance, production, sanitation, and quality. Everyone in the facility must understand that whenever repairs or modifications that could put product at risk are completed, the equipment and environment must be cleaned prior to running any further product. Additionally, those who will execute the program must understand their roles and program execution expectations.

Pre-planning communication is key to success for all projects, planned repairs, PMs, or equipment modifications. Pre-planning communication aids in ensuring that the correct resources are available for both the cleaning and inspection processes of sanitation after maintenance. It is critical to ensure that everyone understands the type of work that will be completed, which will drive the type of cleaning required.

Program Verification

It is not enough to develop a program and assume that it will be executed effectively; the program requires verification. Program verification must include tag documentation review, tag closure verification, and a process to verify that any type of work that required a sanitation-after-maintenance tag had a sanitation-after-maintenance tag. Remember that any type of repair, PM, or infrastructure work that could impact product contact surfaces requires sanitation after maintenance.

Summary

An effective sanitation-after-maintenance program ensures clear roles of everyone involved in a project or repair, clear documentation and tracking, and an execution verification process. Having an effective sanitation-after-maintenance program in place is critical for any food plant to achieve consistent hygienic conditions, food safety, and product quality.